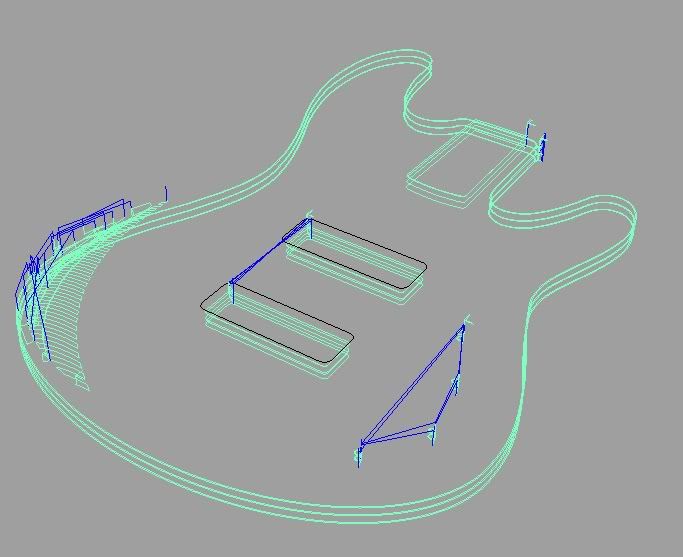

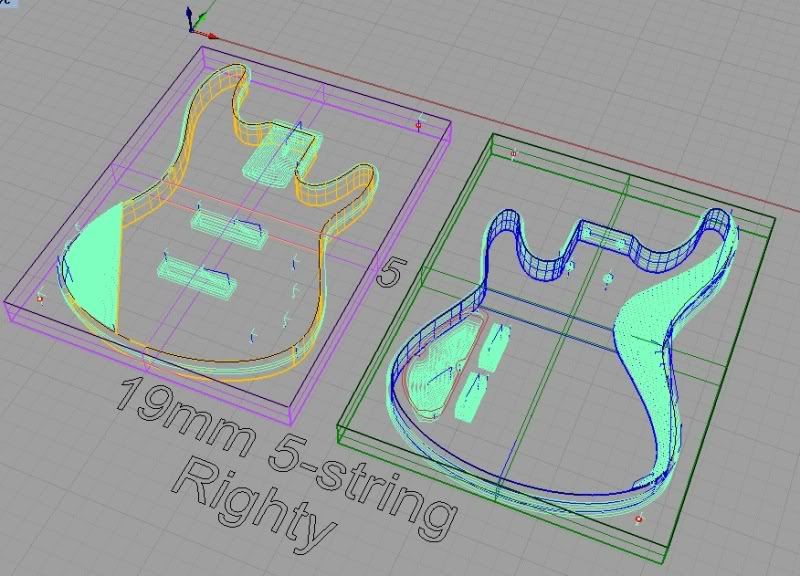

and a peek at my first run at the front side tool paths

all the best,

R

| LeftyBassist.com http://leftybassist.com/ |

|

| new shop CNC deployment http://leftybassist.com/viewtopic.php?f=19&t=2424 |

Page 3 of 3 |

| Author: | Rodent [ September 12th, 2011, 7:32 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

and a peek at my first run at the front side tool paths  all the best, R |

|

| Author: | Rodent [ September 25th, 2011, 8:38 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

I drove it this afternoon! definitely not any kind of serious driving ... more like what I did back in '83 at the new Strippet punch that the shop had just installed ... I manually moved thru the X, Y, and Z axis using my keyboard, sent the tool to absolute home, loaded the gcode I posted earlier today ... and then learned that the gcode I posted had a goof on the Z, and at a default tool path speed of 30 IPM of travel there's not enough time for the Z axis limit switch to stop to servo before it gets stuck in the 'beyond full up' position a quick shut-down of the workstation and power-off of the CNC later, and I was able to manually rotate the z-axis controller below the point where the limit switch activates. a quick power-up of everything and all was good again ... whew!! now I need to discover where I went wrong with my posting so I can fix my Rhino model to suit (or maybe it's as simple as positioning the cutter into a 'relative home' location for that post. I'm sure I'll get it figured out and be cutting foam validation parts in the coming couple of days all the best, R |

|

| Author: | Rodent [ September 27th, 2011, 9:41 am ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

done! I needed to make an adjustment to my part position, and also to 'zero' the spindle once it was in home position. with this step completed, everything runs as I anticipated it would ... I 'virtually' drove the machine (i.e. without a cutter loaded and spinning) thru a complete body side last night to verify that I have all my key reference points properly located and the part properly positioned on the table. I need to re-post my code with proper feed rates, and then I'll test cut a body out of pink poly foam. if that goes well, I'll move forward to a Poplar body blank sometime next week I'm going to see if I can borrow a rocorder to capture a video of the first test cut in foam and wood. if I can, I'll post it to youtube and provide a link to that in this thread (in case anybody is interested in viewing it) all the best, R |

|

| Author: | Rodent [ September 27th, 2011, 10:26 am ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

here's a link of what can be done if you opt for the high $$$$$$$$$$$ 220v 3 horse power internally cooled spindle head (vs. the low $ 110v 2-1/4 horse power router head I have) http://www.k2cnc.com/videos/Guitar/CNC_ ... _K2CNC.wmv I doubt I'll be able to take such deep plunges and feed at 150 inches per minute like this spindle does, and estimate that instead of the 15 minutes to took to cut that body side I'm looking at something more like 30 minutes once I have my feeds and depths worked out for the bits I'll be driving all the best, R |

|

| Author: | andrew [ September 27th, 2011, 2:20 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

Looking forward to seeing the first body you make with the CNC machine. |

|

| Author: | belinmad [ September 27th, 2011, 2:26 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

Yeah, truly looking forward. And very cool video, by the way. |

|

| Author: | Rodent [ September 28th, 2011, 10:07 am ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

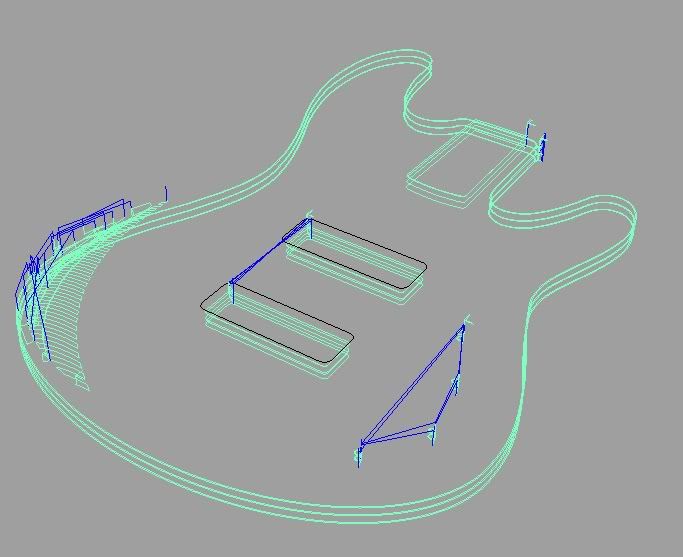

had to do a little bit of tweaking to the CAD model for final tool path creation. here's a look at the final model that was used to generate all of the tool paths  a couple pressing things have come up this week, so my foam cutting extravaganza has been rescheduled for late next week. this will also give me time to get a good grounding strap installed so that static build-up passes directly to ground and not thru my computer controller on its way to ground all the best, R |

|

| Author: | Rodent [ September 28th, 2011, 3:05 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

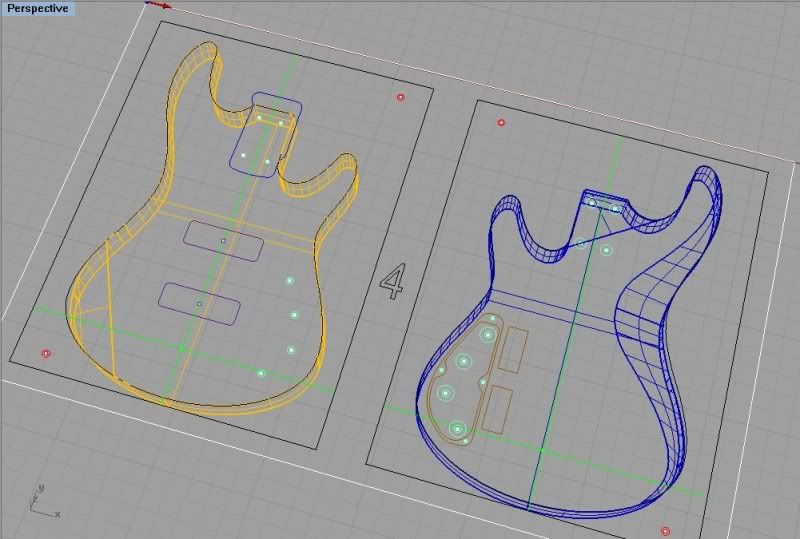

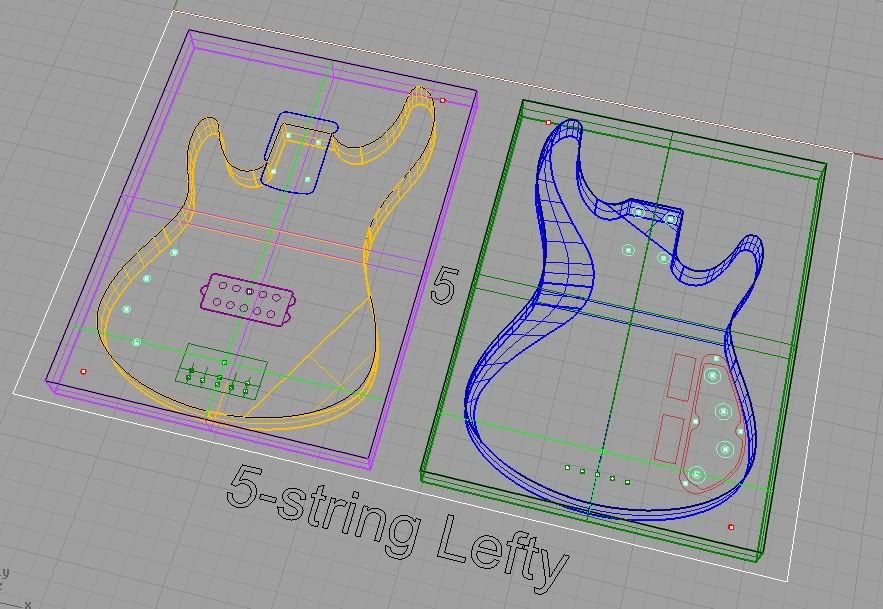

probably better to show the lefty version, eh?  all the best, R |

|

| Author: | Rodent [ October 8th, 2011, 5:00 pm ] |

| Post subject: | Re: somebody pinch me! (new shop CNC has finally arrived) |

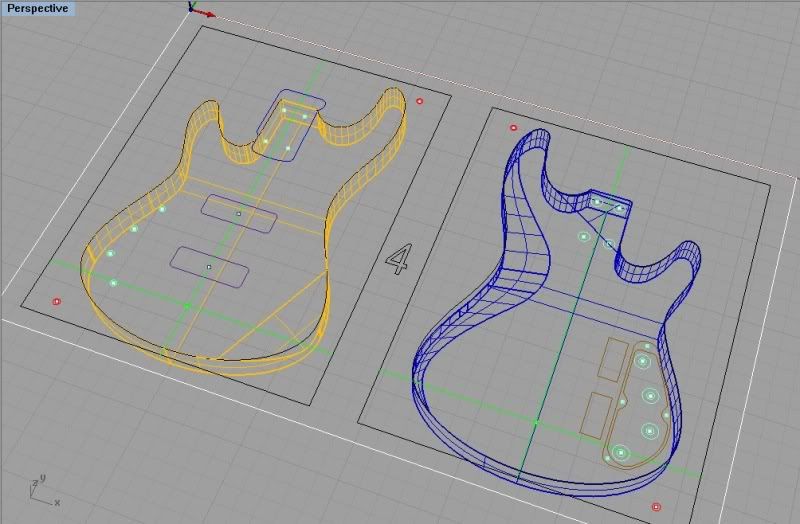

just finished designing the CAD model and tool paths for the 5-string righty. I'll morph this into the lefty version as soon as I validate the tool paths  at the rate I'm pushing thru remaking all of my designs in CAD, I should be able to initiate work on the 6-string single-cut before the end of the year (sooner if my day-job allows to to continue working from my home office) all the best, R |

|

| Author: | Rodent [ October 12th, 2011, 4:41 pm ] |

| Post subject: | Re: new shop CNC deployment |

and here's a peek at the 5-string lefty version, shown in a configuration that utilizes a Type A thru-body bridge and MM style pickup (this is only one of the many configurations I now have modeled)  now it's on to tool path definitions so I can cut the first lefty 5-string proofing body blank ... all the best, R |

|

| Author: | Rodent [ October 15th, 2011, 9:58 pm ] |

| Post subject: | Re: new shop CNC deployment |

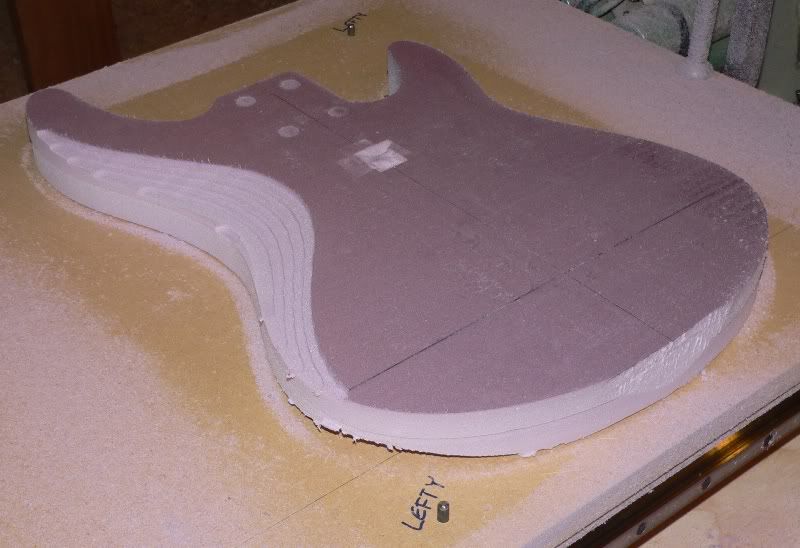

and so the total purple statification begins! here is the first proofing body I'm running on the CNC - a 5-string lefty with a single P pickup so far today I have validated my tool paths for the alignment pin holes, neck pocket, pickup cavity, top routed control cavity, body perimeter, and the first roughing pass of the forearm contour. this image shows a ball mill loaded into the router in advance of its second attempt at its proofing pass (the first attempt revealed that I had the feed rate waaaay too slow, so I'm taking a break to get it bumped up to a more realistic feed speed. it's getting late, so testing the new code will probably have to wait until tomorrow  what a stinkin' static mess all those purple foam pieces are all the best, R |

|

| Author: | Rodent [ October 16th, 2011, 7:22 pm ] |

| Post subject: | Re: new shop CNC deployment |

rear side gut-cut and body perimeter roughed out. you can see the alignment pins I use to precisely locate the body when flipping it to cut the rear side  next pass with the CNC will detail the perimeter edge, and then I'll swap cutters to a ball mill to detail the gut-cut I think I'm ready to cut wood now to decide ... P pickip only, or make this a PJ instead. hmmm ..... all the best, R |

|

| Author: | Rodent [ October 18th, 2011, 7:35 am ] |

| Post subject: | Re: new shop CNC deployment |

done!  on to a wood body blank this coming weekend all the best, R |

|

| Author: | AzWhoFan [ October 18th, 2011, 10:26 am ] |

| Post subject: | Re: new shop CNC deployment |

"Barney blank" LOL !!! if it makes any difference, I'll vote for SCPB pup. |

|

| Author: | Rodent [ October 18th, 2011, 10:55 am ] |

| Post subject: | Re: new shop CNC deployment |

you saw the FB post (hence the 'Barney' body reference, for those who haven't seen it) I have a custom 5-string SCPB sitting in a box waiting for a project. don't know that I'd be able to fit another bass into my teeny NAMM booth space (I'm already exceeding by a couple basses what will fit on the wall space and floor stand ... so look for a couple basses to be sitting in other booths [like a certain amp manufacturer or two]) current plans are to have a lefty 4-string SCPB model in the booth all the best, R |

|

| Page 3 of 3 | All times are UTC - 8 hours [ DST ] |

| Powered by phpBB © 2000, 2002, 2005, 2007 phpBB Group http://www.phpbb.com/ |

|