after what seems like forever, I'm now able to offer fretboard blocks-n-binding as an option for all new RGW basses. unfortunately, this is by no means an inexpensive option since my cost for B&B is greater than what it costs for a regular birdseye/birdseye neck

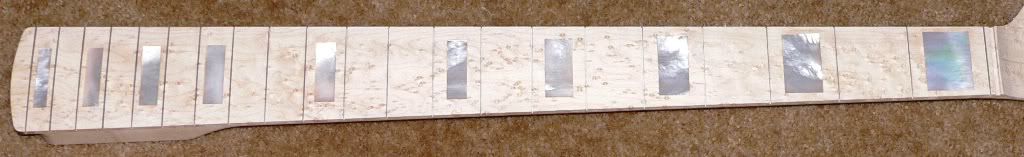

Here's a pair of images for a client build where the client wanted blocks of a constant width that did not increase as the neck widened. These are 1/16" thick real shell and not imitation plastic. I wish they would photograph as well as they look in person. And check out how crisp those corners are!!!

Please note that these are installed on a rough fretboard that has not been finish sanded. It's still in need of a load of work before this collection of wood, graphite, glue, and steel becomes a playable bass neck.

And just in case you've ever wondered what a neck looks like when it's fresh off the CNC, here's a pair of images that should satisfy your curiosity. If you look closely you can still see the tool marks where the router head hem-stitched multiple passes to form the rough rear profile. there's still a lot of detailed hand-work to go from here - but now you can see that utilizing CNC in no way eliminates the need for craftsmanship in bringing the final neck to life

all the best,

R